Cemented carbide roll ring, also known as Tungsten carbide roll ring, possesses very good thermal conductivity property. Under the condition of high temperature, compared to other materials, the hardness keeps stable and it provides much better heat resistance, wear resistance and strength.

The cemented carbide roll ring has been invented with the appearance of high speed wire rod mill, it is now widely applied in the production of high speed wire, bar and thread rod steel. Its hardness and wear resistance come from tungsten carbide (Wc) while the toughness and strength depend on the binding agent (Co-Ni-Cr).

We know that each customer has his own production line condition. According to the specific machine and work condition of each customer, we provide our expertise to our customers and help them to make the best solution for the production requirement. Honsin Cemented carbide rings solutions help our customer to reduce the down time and increase our customers’ productivity.

We supply rings according to the customer’s drawing. Your Inquiry will always under attentive consideration. Our engineers are actively involved to solve each single and unique need of each customer.

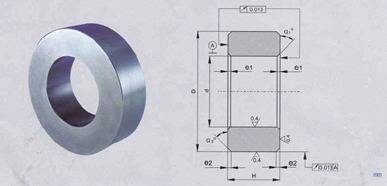

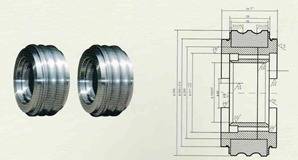

Dimension and precision of finished carbide roll rings

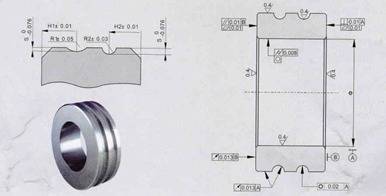

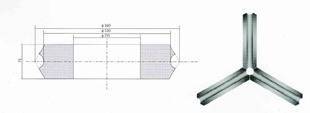

Three dimensional carbide roll rings

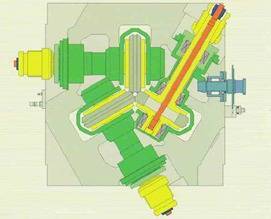

- KOCKS rolling mill structural plan

- Three dimensional carbide rolls for cold rolling for ribbed steel bars

Cemented carbide roll rings for seamless steel pipe

Cemented carbide roll rings is used on the stretch reducing mill for seamless steel pipe with the durability ten times higher compared to common roll. The surface quality and the steel pipe size accuracy are greatly improved. The Cemented carbide solution reduces effectively the production cost and improves the quality.

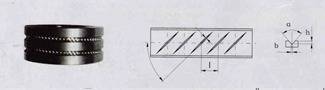

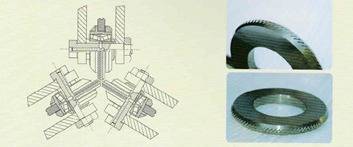

Composite cemented carbide roll rings

The cemented carbide composite roll

The cemented carbide composite roll is mainly used on the finishing mill for bar, thread steel bar and common wire. The adapted cemented carbide composite roll solution reduces the frequency of changing groove and rolls, thus to reduce the labor intensity, production down time, and improve greatly the work efficiency. Regarding the final product aspects, the surface and intrinsic quality can be improved which provides remarkable productivity for our customers.