Centrifugal Casting Alloy Indefinite Chilled Roll

Centrifugal Casting Alloy Indefinite Chilled Roll

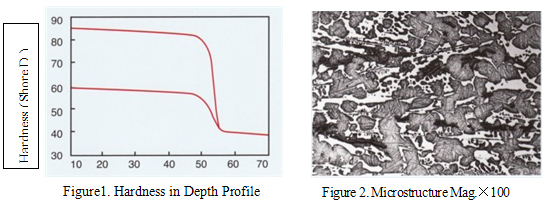

The outer layer exhibits a remarkable mechanical performance and the quantity of graphite in the roll work layer remains basically unchanged along the depth, producing therefore no adverse effect on the decrease of hardness of work layer. The hardness of roll depends mainly on type of matrix (sorbite, bainite, martensite).

Mechanical properties

| Hardness of shell | HSD60-85 |

| Hardness of core | HSD35-48 |

| Tensile Strength of core | ≥450MPa |

Chemical properties

|

Material |

Hardness (HSD) |

C |

Si |

Mn |

Ni |

Cr |

Mo |

|

Indefinite I |

60-70 |

3.0/3.5 |

0.5/1.0 |

0.5/1.0 |

0.5/1.0 |

0.5/1.0 |

0.2/0.6 |

|

Indefinite II |

62-72 |

3.0/3.5 |

0.5/1.0 |

0.5/1.0 |

1.0/2.0 |

0.5/1.0 |

0.2/0.6 |

|

Indefinite III |

65-75 |

3.0/3.5 |

0.5/1.0 |

0.5/1.0 |

2.0/3.0 |

0.7/1.2 |

0.2/0.6 |

|

Indefinite IV |

70-80 |

3.0/3.5 |

0.5/1.0 |

0.5/1.0 |

3.0/5.0 |

1.0/2.0 |

0.2/0.6 |

Application

For continuous processing of strips and bars, pre-rolling of high-speed wires on front racks of finish roll mills for immediate or finish rolling of sections or for thin plate and straightening process.