Centrifugal Casting Definite Chilled Cast Iron Roll

Centrifugal Casting Definite Chilled Cast Iron Roll

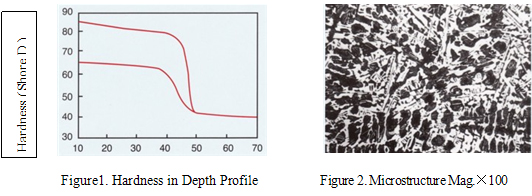

The rolls exhibit improved mechanical properties due to presence of chilled surface structure and the change of pine-tree-like structure . The hardness and type of matrix of roll depend on conditions of application. The roll produced with centrifugal method basically eliminates the presence of graphite in its work layer while the core is made of nodular cast iron, increasing as a result, both the wear-resistant and breaking strength.

Mechanical properties

| Hardness of shell | HSD65-85 |

| Hardness of core | HSD35-48 |

| Tensile Strength of core | ≥450MPa |

Chemical properties

ApplicationFor wire, bar and small section or light-duty material rod mills. |