Forged Intermediate Rolls

Forged intermediate rolls

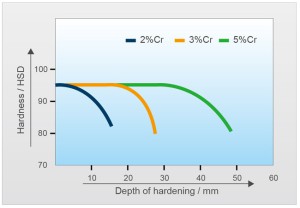

Forged steel intermediate roll applies to high precision 6-Hi(as well as a few 8 Hi) mills. its name is from the working location between working roll and back-up roll. The intermediate rolls are mainly used to control the shape of strip. The different Materials of 2%Cr,3%Cr,5%Cr and semi-high speed steel (SSH) can be used according to different requirements of hardness depth.

Harndess Curve of Intermediate Roll

Physical properties

| Symbol | Hardness | Hardness Uniformity | Depth of hardness | Size |

| 9Cr2Mo | 85-102 HSD | 3HSD | 8~15mm | ¢200-600mm |

| MC3 | 85-102HSD | 3HSD | 15-30mm | ¢200-1000mm |

| MC5 | 85-102HSD | 3HSD | 20-40mm | ¢300-1000mm |

Application

| Symbol | Type of material | Application for cold mills |

| 9Cr2Mo | 2%Cr | Work rolls for general 4 HI mill |

| MC3 | 3% Cr | Work rolls and intermediate rolls for reverse cold mills. |

| MC5 | 5% Cr | Work rolls for tandem mill and skin pass mill |

Other dimensions or materials requirements can be produced under customers requirements.