Centrifugal and Static Casting Steel Base Adamite Roll

Its micro-structure is composed of matrix and carbide with carbon content of 1.3-2.3%,depending on content of alloy and heat treatment process. The matrix consists of pearlite and bainite, with the addition of Cr, Mo and Ni for higher stability of carbide, enhanced high-temperature resistance and strengthened matrix, the roll has the special merits of being small in drop of hardness, highly wear and high-temperature resistant, and high in load bearing capacity feature etc.

Mechanical properties

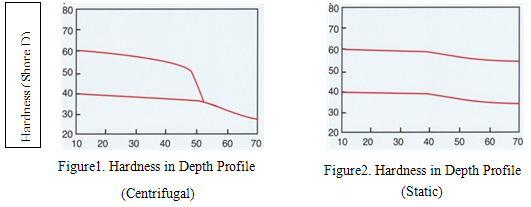

| Centrifugal | Static | |

| Hardness of shell | HSD 40-60 | HSD 40-60 |

| Hardness of core | HSD 35-50 | HSD 40-55 |

| Tensile Strength of core | ≥450MPa | ≥420MPa |

Chemical properties

|

C |

Si |

Mn |

Ni |

Cr |

Mo |

|

1.3/2.3 |

0.3/0.6 |

0.6/1.2 |

≥0.2 |

0.8/1.6 |

0.2/0.6 |

Application

Mainly used for the front stand of section mill and hot strip mill, for front housing of finishing mill and the wire mill. Also used for roughing and intermediate mill stand.