Centrifugal Casting High Speed Steel Roll

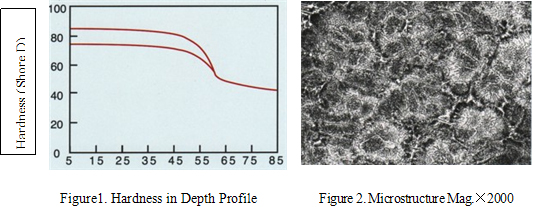

The outer layer is a complicated carbide structure of high-carbon steel alloys containing Cr、Mo、W、V、Ni and Nb, which is inlaid into the martensite structure. Through control of carbon control and comprehensive heat treatment process, the roll shows optimal wear and thermal fatigue resistant properties and surface of the oxide assumes a film structure. The residual stress is also reduced to a minimum.

Mechanical properties

| Hardness of shell | HSD75-85 |

| Hardness of core | HSD35-48 |

| Tensile Strength of core | ≥450MPa |

Chemical Properties

|

C |

Si |

Mn |

Cr |

Mo |

W |

V |

Nb |

| 1.6/2.3 | 0.3/0.9 | 0.2/0.8 | 3.0/6.0 | 3.0/6.0 | 1.0/4.0 | 2.0/6.0 | 1.0/3.0 |

Application

Widely used as the F5 and F6 working rolls for strip hot mills, high-speed wire mills, on pre-finish mill stand bar finish milling dividing-shear stand.