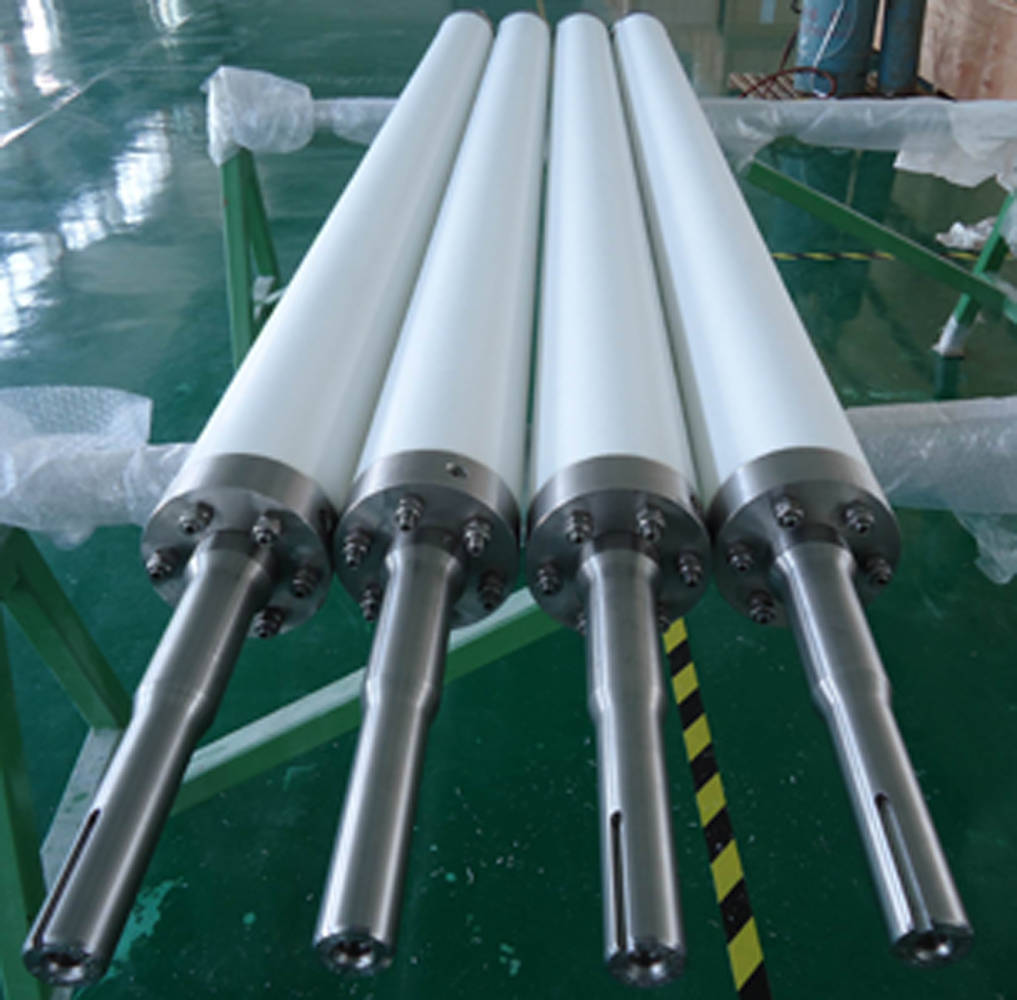

Ceramic Rolls for high temperature furnace

Other ceramic rolls are available with the materials below :

- Honsin Ceramic Roll® Series- Fused Silica Ceramic Roller (Presentation below)

- Honsin Ceramic Roll® Series- Alumina Ceramic Roller (contact us)

- Honsin Ceramic Roll® Series-Nitride Bonded Silicon Carbide (NSIC) (contact us)

- Honsin Ceramic Roll® Series-Reaction Bonded Silicon Carbide Ceramic (RSIC) (contact us)

Fused Silica Rollers present excellent mechanical properties and very special surface quality, They are used as transport rollers for tempering flat glass, PDP solar, silicon steel industry, Continuous Annealing Line (CAL), Continuous Galvanizing line (CGL) and also automotive furnace. Honsin Ceramic Rolls are successfully used throughout the world for the various applications such as:

- Fused Silica Rollers for glass annealing furnace and tempering furnace

- Fused Silica Rollers for automotive furnace (coating/hot stamping)

- Fused Silica Rollers with heat resistance metal shaft for continuous annealing line, continuous galvanizing line and Silicon steel processing

- Fused Silica Rollers for steel processing and non-ferrous metal processing

Fused Silica Rollers for glass annealing furnace and tempering furnace

Fused Silica Rollers with heat resistance metal shaft for metal processing

Our process begins by choosing the fined high purity fused quartz as material, on the basis advanced molding and processing manufacturing line, our products are recognized by our customers as innovative and reliable. We offer our Fused Silica rollers with metal shaft and end cap in a variety of designs and material grade. Our experience benefits each customer to choose the right combination of rollers for both metal part and Fused Silica part.

Main physical properties:

- Deformation proof and resisting heavy loading

- Excellent thermal stability & thermal shock resistance

- Excellent thermal insulation

- Very low thermal expansion coefficient

End Caps: (Stainless steel or 45C material)

A variety of end cap designs are available depending upon the application temperature, furnace design and drive system. These include popular RTV silicon bonded caps, custom designs, patented high temperature caps.

Properties table

| Item |

value |

| Fused silica (SiO2) |

> 99.7% |

| Cristobalite |

< 2% |

| Bulk density (g/cm3) |

1.92 1.99 |

| Apparent porosity (%) |

6 – 12 |

| Service temperature (°C) |

Up to 1,200 |

| Thermal expansion coefficient (×10-6 /°C)* |

≤ 0.6 |

| Thermal conductivity (W/m°C)* |

< 0.65 |

| Thermal shock resistance (25 1200°C) |

Very good |

| Bending strength (room temperature) (MPa) |

≥ 25 |

| Bending strength (1100°C, 0.5 hour) (MPa) |

≥ 28 |

| Compressive strength (room temperature) (MPa) |

≥ 60 |

| Tolerance in diameter (mm)* |

± 0.05 |

| T.I.R. over full length: (mm)* |

< 0.12 |

| Surface roughness (μm)* |

< 1.6 |